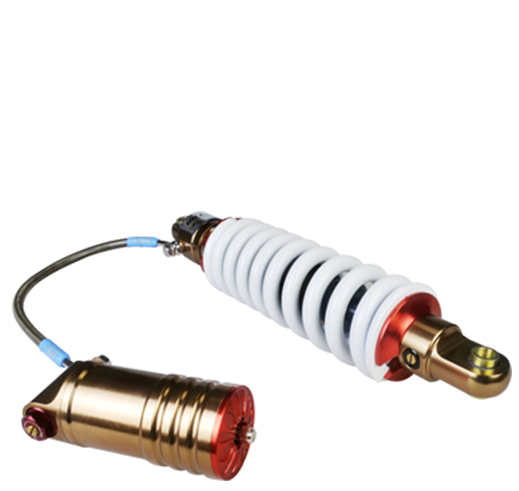

1. Make the car stop after driving 10km on the road with poor road conditions. Touch the shock absorber shell with your hand. If it is not hot enough, it means there is no resistance inside the shock absorber and the shock absorber does not work. At this time, appropriate lubricating oil can be added, and then the test is carried out. If the shell is hot, the oil inside the shock absorber is short of oil. Full oil should be added; otherwise, the shock absorber fails.China bicycle shock absorbers manufacturers

2. Press the bumper hard and release it. If the car jumps 2 or 3 times, the shock absorber is working well.

3. When the car runs slowly and brakes urgently, if the car vibrates violently, it indicates that the shock absorber is defective.

4. Remove the shock absorber to stand it upright, and clamp the lower connecting ring on the vise, pull the damping rod for several times, and then there should be stable resistance, the resistance of pulling up should be greater than when pressing down The resistance, such as unstable resistance or no resistance, may be due to lack of oil inside the shock absorber or damage to valve parts, and repair or replacement parts should be performed.

English

English 简体中文

简体中文 Việt nam

Việt nam भारत

भारत ไทย

ไทย